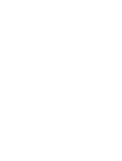

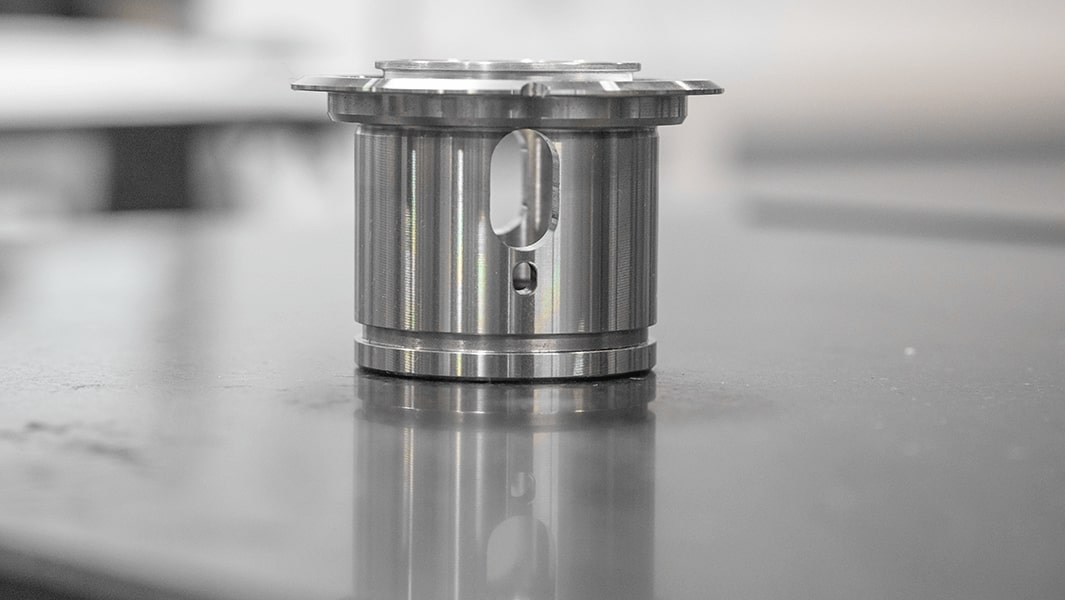

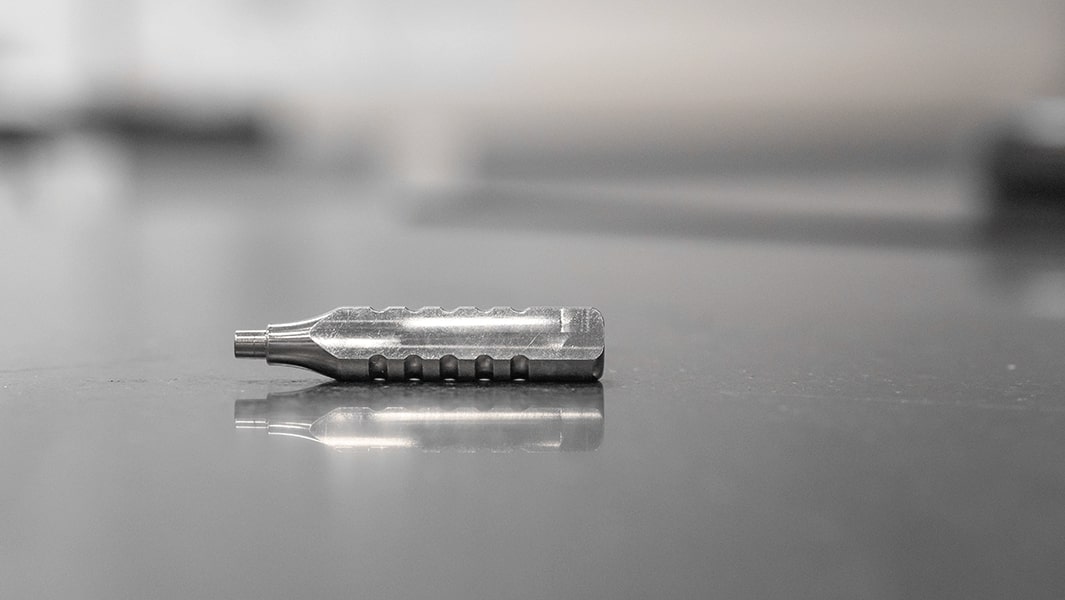

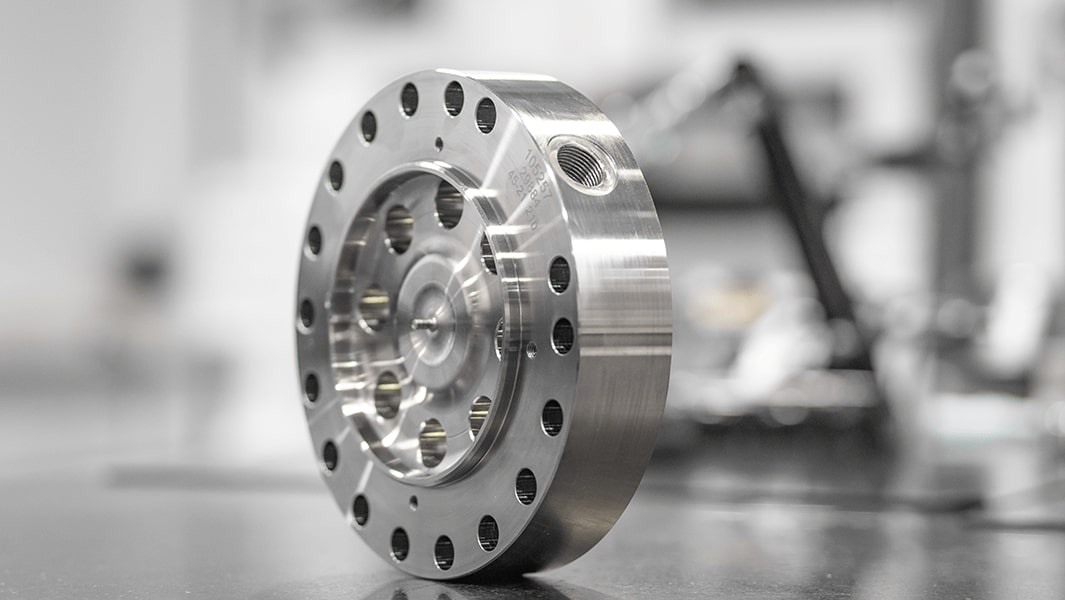

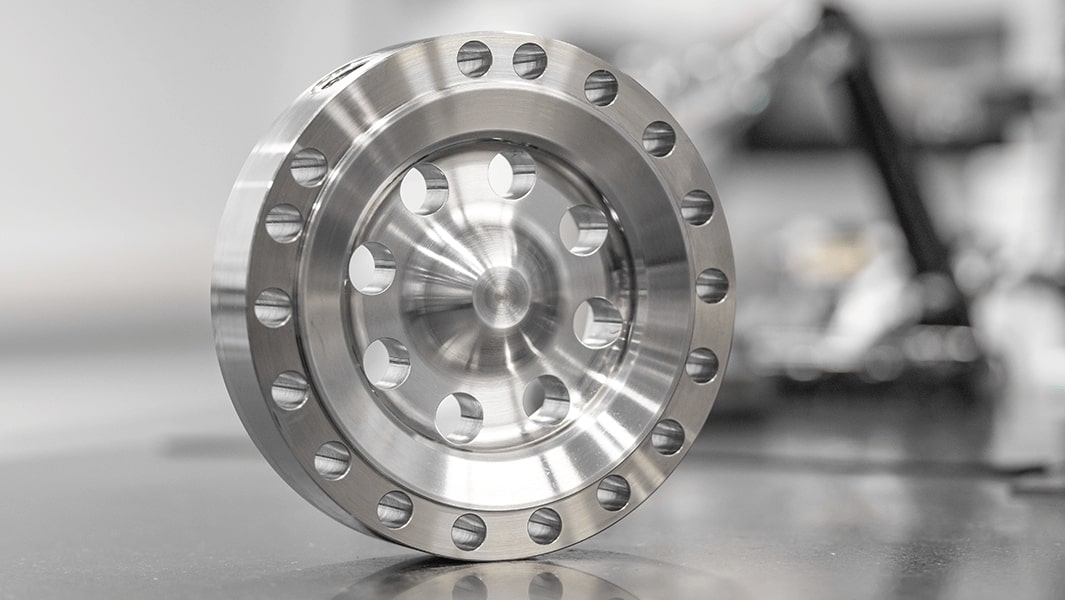

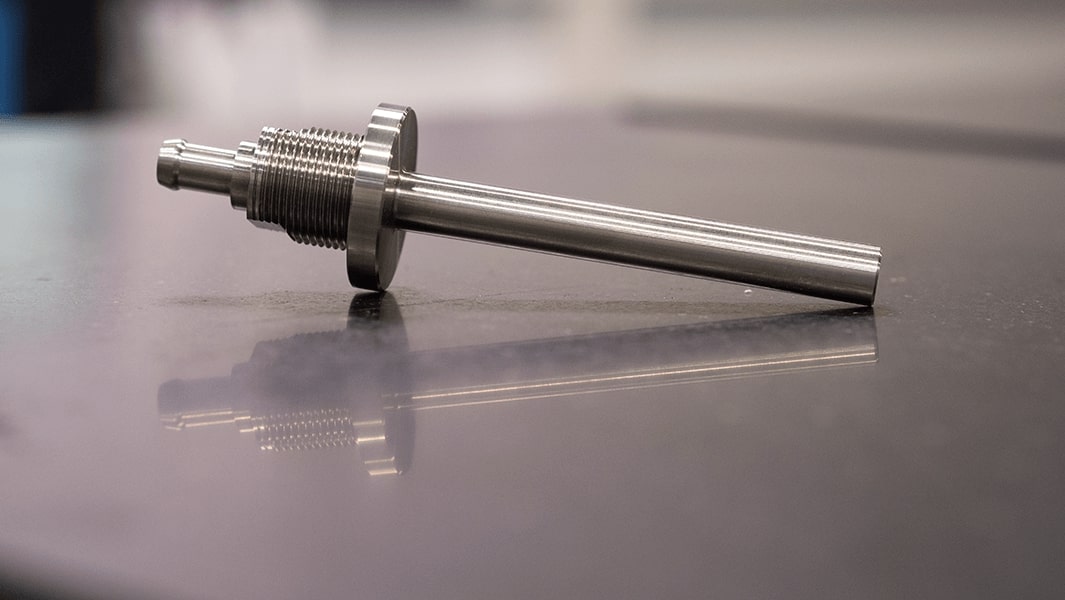

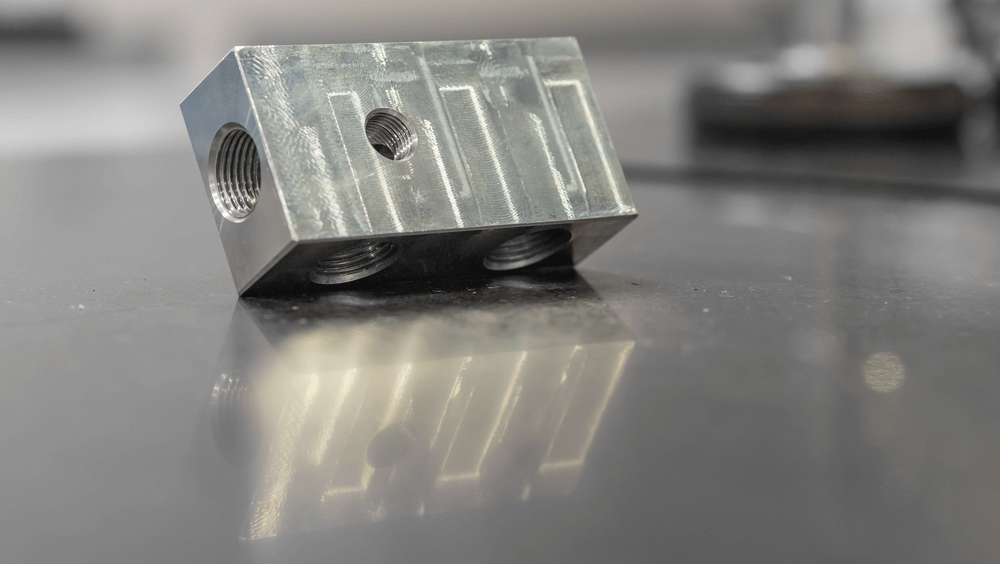

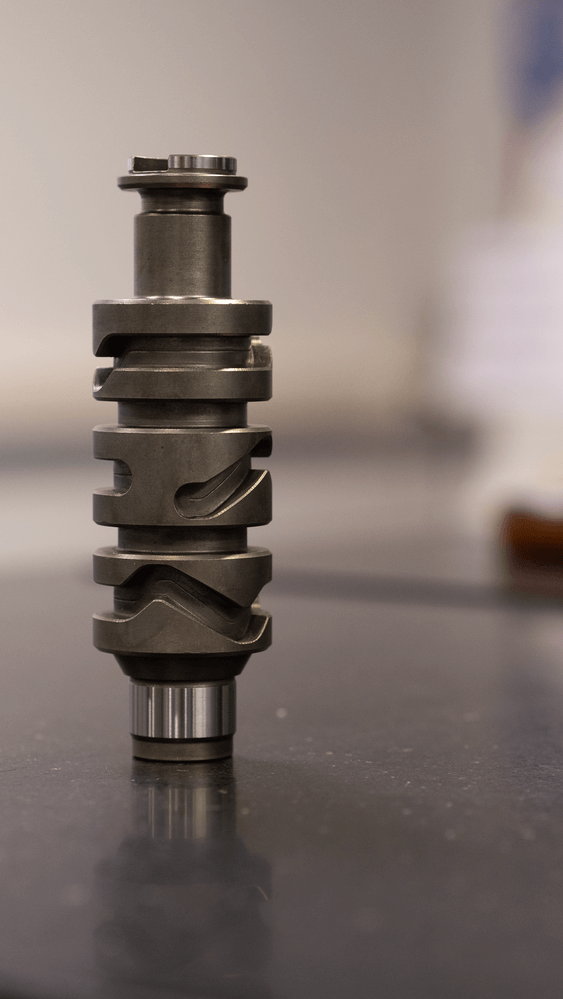

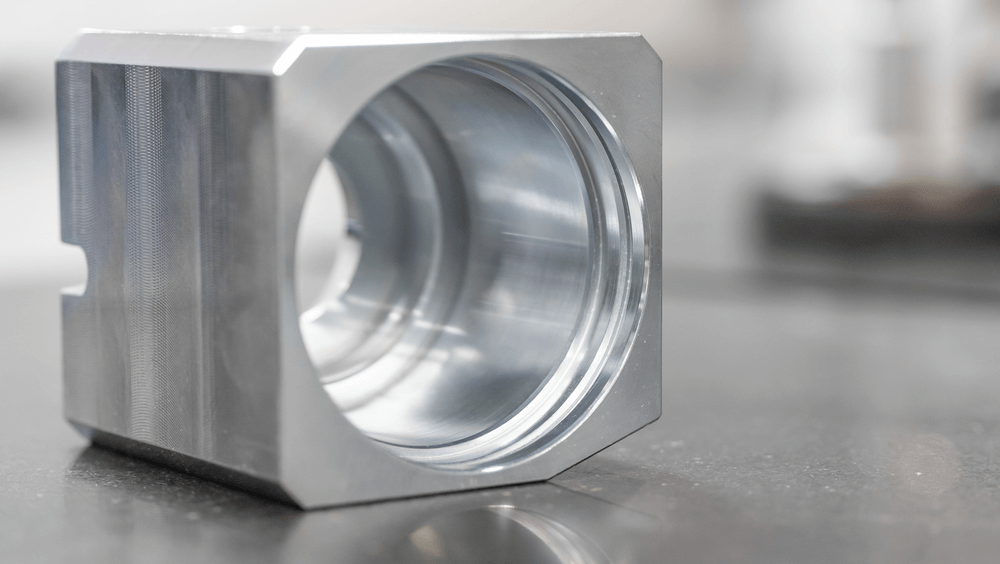

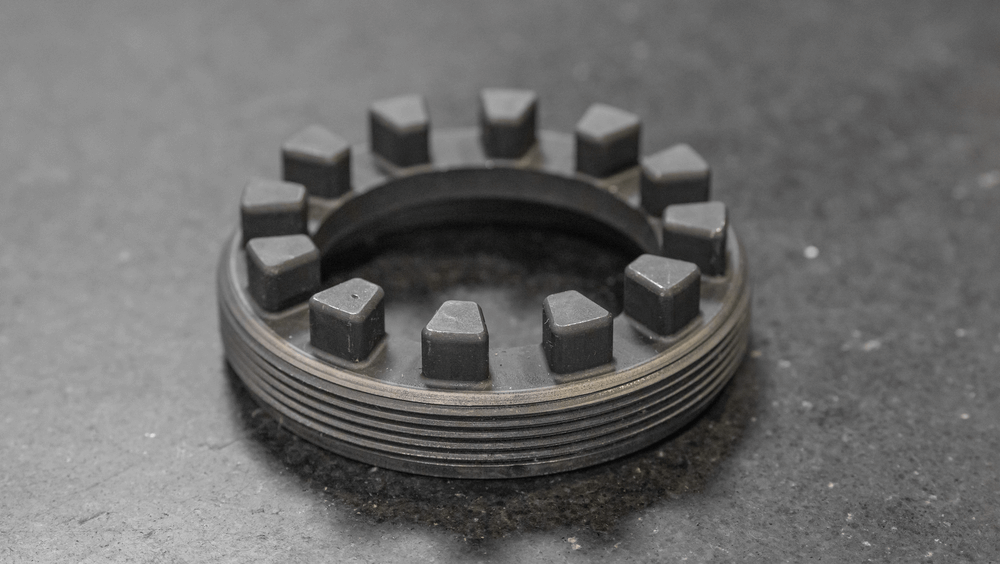

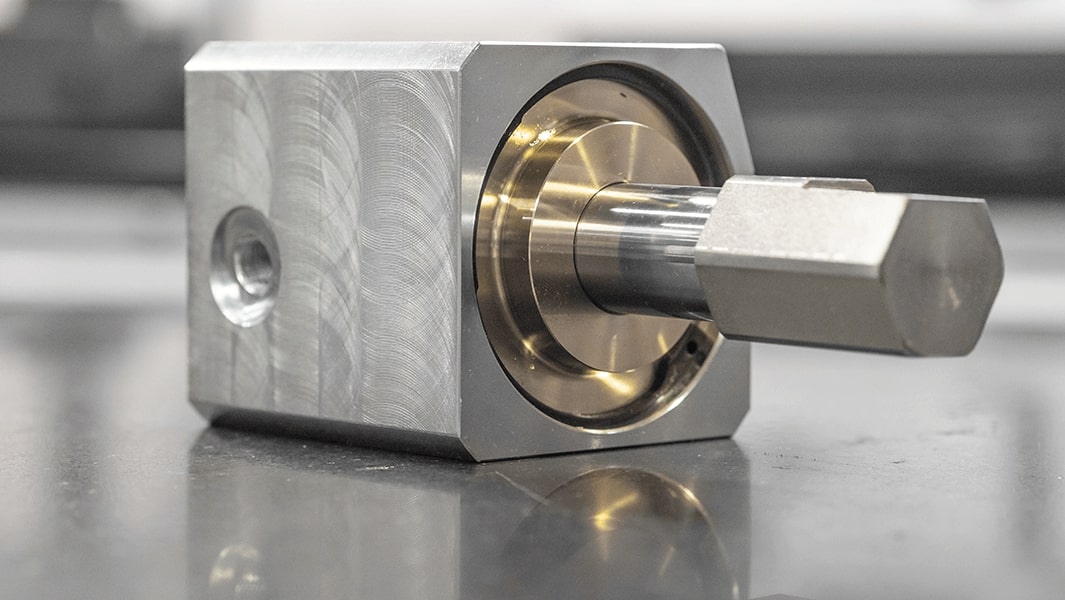

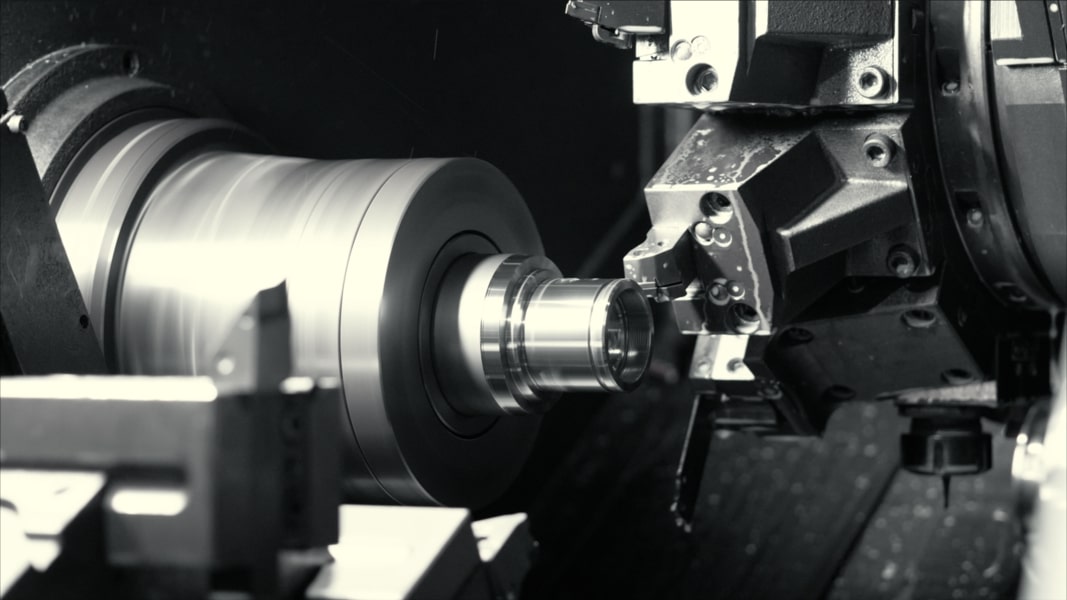

The heart of Boano Srl is its production department, equipped with state-of-the-art machinery and highly skilled personnel to ensure continuous operation. For precision work, the company has a complementary machine park, constantly updated and subject to regular maintenance. Tooling is managed through automated warehouses. Special tools are designed in-house through constant and direct interaction with production departments. This activity allows for the best optimization of processing cycles.

Our machinery is divided into two categories: CNC lathes and conventional mechanical lathes.

CNC Lathes

Mechanical Lathes

TURNING DEPARTMENT

CNC LATHES FOR HIGH PRECISIAON MACHINING

Our CNC lathe park is equipped with 27 state-of-the-art machines, capable of producing parts with the highest precision.

Our versatile fleet includes single and double spindle lathes, with fixed and movable steady rests, bar feed and chucking, and robotic loading. We can machine bar stock up to Ø 80 and chucking up to Ø 400.

- N°2 DMG MORI NLX 2500/700

- N°4 BIGLIA B465 T2 Y2

- N°2 BIGLIA B470 YSM

- N°2 MORI SEIKI ZL200

- N°1 MORI SEIKI SL250

- N°5 MORI SEIKI CL200 di cui uno con Gantry Loader

- N°2 TAKAMAZ X180 con Gantry Loader

- N°2 HWACHEON HI-TECH 230

- N°1 DMG MORI ECOTURN 450

- N°1 TAKAMAZ X10

- N°1 HS-327 9AX.

- N°2 HANWHA SL35 HPII

- N°2 ITS NORIS 65

Single spindle and multi-spindle lathes

Torneria Meccanica

Our department is equipped with 10 Index single-spindle lathes for medium-sized series with bar feed up to Ø 60. For larger series, we utilize 2 multi-spindle lathes. To complete the machining process, we employ automatic drilling and milling machines. In the past year, we have added a deep hole drilling machine capable of drilling up to 500mm.